testing zinc coating thickness|zinc plating thickness chart : member club 8 Accelerated test methods applied to zinc coatings . proportional to the thickness of the coating. The operational sequence for applying the selected system should be determined in consultation with the steel fabricator and the applier of the zinc coating system. 22 de fev. de 2021 · A resposta a esta pergunta é: não! Ao contrário da PM-RJ e, até mesmo, das polícias civis de outros estados, a polícia civil do Rio de Janeiro não exige .

{plog:ftitle_list}

webTelegram contact with @GrupoTuga Arte. Arte. Entra já! https:/telegram.im/ArteTuga 👄🇵🇹 https:/telegram.im/+UF5L-a1JqCs5YTA8. Send message via Telegram app. Don't have .

Coating thickness measurement/Dry film thickness measurement is used to determine the thickness of coatings on components and to monitor the coating process. Our measuring instruments solve a wide range of applications in . This translates to around 0.0008 inches (21 microns) of zinc on each surface for a coating evenly applied to both sides of the sheet. The coating thickness must be measured, the coating peeled off, and the steel substrate .coated sheet. For a coating equally applied to both sides of the sheet, this means there is about 0.0008 inches (21 microns) of zinc on each surface. To accurately determine the thickness of the coating, the coated thickness must be measured, the coating stripped off, and then the steel substrate thickness measured using a gauge capable8 Accelerated test methods applied to zinc coatings . proportional to the thickness of the coating. The operational sequence for applying the selected system should be determined in consultation with the steel fabricator and the applier of the zinc coating system.

A Note on Accelerated Testing. Claims that any of the above zinc coating methods are superior to HDG for fasteners stem from the results of accelerated testing, specifically the published results of various salt spray tests (ASTM B117, etc.) available from a competitors website. . In addition, zinc coating thickness is directly related to .

The specification ASTM A123/A123M Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products, covers individual steel pieces as well as assemblies of various classes of material. The requirements listed in ASTM A123/A123M include coating thickness, finish, appearance, and.

Coatings for Corrosion Protection: Metallic. S.R. Taylor, in Encyclopedia of Materials: Science and Technology, 2001 2.1 Zinc Coatings. Zinc is an easily applied (e.g., hot dipping), low-cost, and effective coating on steel from a corrosion standpoint, and thus represents one of the most commonly used metallic coatings (Porter 1991).It is used extensively in buildings, cars, .However, measuring coating thickness is only one of the many specification requirements in the inspection process. The inspection of hot-dip galvanized steel is simple and quick, and the two properties of the hot-dip galvanized coating . zinc metal used in the process. Testing methods and interpretation of results are covered in the .

The photomicrograph below is a cross-section of the galvanized steel coating, showing a typical microstructure comprised of three alloy layers and a layer of pure metallic zinc. Coating Thickness The American Society of Testing and Materials .Zinc Coating Thickness Requirements: ASTM A153 vs. F2329 Dimension ASTM A153 ASTM F2329 Avg. Coating Thickness of . (Production Lot) Avg. Coating Thickness of Specimens Tested (Batch Lot) Avg. Coating Thickness of Any Individual Specimen Class A – Castings – Malleable Iron, Steel 3.4 mils 86 μm 3.1 mils 79 μm N/A N/A N/A .Table 2 indicates that the galvanizing thickness of Coating Grade 100 is 100 microns or 3.9 mils. The weight of the galvanizing is 705 grams/square meter or 2.3 ounces/square foot. Methods for Measuring Galvanizing Weight or Thickness. Coating weight or thickness can be measured by one of four methods.

2.1.2 AASHTO M 300, Standard Specification for Inorganic Zinc-Rich Primer 2.1.3 AASHTO R 31, Standard Practice for Evaluation of Coating Systems with Zinc-Rich Primers 2.2 American Society for Testing and Materials (ASTM) 2.2.1 ASTM A6, Specification for General Requirements for Rolled Structural Steel Bars, Plates,NOTE 1— Use the information provided in 8.1.2 to obtain the approximate coating thickness from the coating weight [mass]. Minimum RequirementD Triple-Spot Test Single-Spot Test Inch-Pound Units Type Coating Designation Total Both Sides, oz/ft2 One Side Total Both Sides, oz/ft2 Zinc G360 3.60 1.28 3.20 G300 3.00 1.04 2.60 G235 2.35 0.80 2.00The requirements listed in ASTM A123/A123 M include coating thickness, finish, appearance, and adherence. The specification requirements for coating thickness only contain minimums, there is no maximum coating thickness limitation in the specification. . Practice for Testing Chromate Coatings on Zinc and Cadmium Surfaces. This practice is .The PosiTector 200 Ultrasonic Coating Thickness gage non-destructively measures a wide variety of applications using proven ultrasound technology. Measure paint and coating thickness over wood, concrete, plastic, and .

A coating thickness gauge is an essential quality assurance tool when anodizing, galvanizing and applying zinc coating to metallic surfaces. A coating thickness gauge also is used to measure body paint thickness and .ASTM B633 Plating Specifications. About ASTM Plating Specifications. The American Society for Testing and Materials (ASTM) develops technical standards in manufacturing that have been adopted by various industries to enhance performance, safety and ensure higher-quality products.. ASTM specifications are among the most common standards used for Zinc and .

1.1 This specification covers zinc coatings applied by the hot-dip process on iron and steel hardware. The hot-dip galvanizing process consists of parts being immersed in molten zinc for a sufficient time to allow a metallurgical reaction between iron from the steel surface and the molten zinc, resulting in the formation of Zn/Fe alloy layers bonding the coating to the .

B14 – Conductivity Testing; B16 – Coating Thickness Measurement. B21 – Paint Color and Gloss Testing; B22 – Solvent Resistance Testing; B23 – Other Testing In Support of AC7108; . The zinc coating creates a physical barrier that prevents rust from reaching the underlying metal surface. Zinc is chosen because of its innate ability to .

We have the following test meter: Microprocessor coating thickness gauge "Minitest 3001". But we don't have any operating manual for this test meter. On pressing ON button it gives the "E02" code. . I would like to measure the coating thickness of electroplated zinc over mild steel by coulometry. The equipment manufacturer suggested to remove .The protection from the zinc plating is proportional to the thickness of the zinc plating - so thicker zinc means more protection for the base metal. Thickness has almost no effect on the resistance to "white rust" because this involves the coating itself corroding.

Laboratory PFI Beater φ250×52 distribution

This uniformity of the zinc thickness is typically given within a batch on the supplied sheet that still has to be formed. When the body parts are formed, flowing or even scraping off of the zinc coating may occur in the areas of severe bending radii, and this may vary thickness by 3 and 9 microns, and occasionally remove the coating altogether.Choose from our selection of thickness testers, including economy pocket dial thickness gauges, digital coating-thickness gauges, and more. In stock and ready to ship.

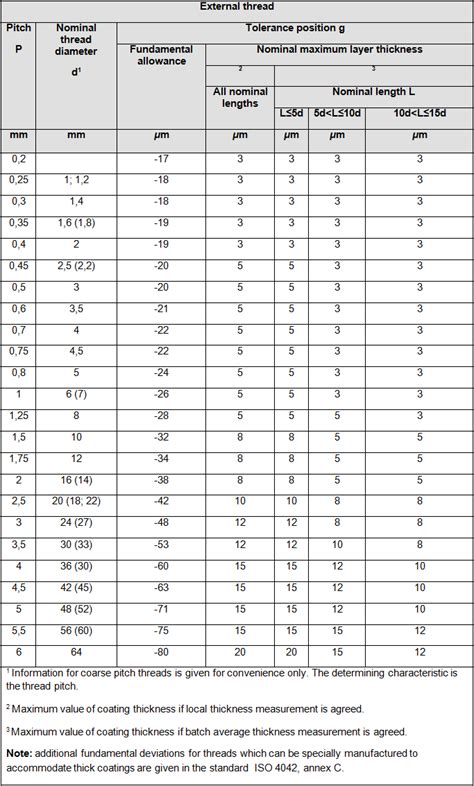

Contact the GalvInfo Center The usual criterion for determining the expected service life of zinc coatings is thickness: the thicker the coating, the longer the service life. Hot-dip galvanizing (batch or continuous), electrogalvanizing, zinc plating 1.7 mils (43µm) Zinc Spraying (metallizing) 1.9.The composition of the zinc in the galvanizing bath shall comply with AS/NZS 4680. COATING REQUIREMENTS . Appendix G. In the event of any dispute, an independent test shall be carried out. 2 Surface Finish. The galvanized coating shall be continuous, adherent, as smooth and evenly distributed as possible, and free from any defect that is .solution for zinc coating thickness measurements. INSTRUMENTAL FT110A The Hitachi High-Tech Analytical Science FT110A is a high performance, . thickness measurement and composition analysis. Measurements can be made according to international test methods, ISO 3497 and ASTM B568. The FT110A uses a proportional counter for a cost effective .Applied Technical Services’ technicians offer professional coating services, including zinc plating thickness measurements and coating testing and inspection services. Our metallurgy lab employs chemists, engineers, and other specialists with decades of shared experience in various metallurgy services.

zinc plating thickness chart

Laboratory Pulp Aquapulper — Frequency Controlled-12L distribution

Laboratory Flotation Cell distribution

Laboratory pulp dehydrator distribution

Differential Scanning Calorimeter distribution

Resultado da Online bestelt u eenvoudig een VCS-slotje met twee sleutels. Deze passen op vrijwel iedere brievenbus en meubel. Wanneer een brievenbus niet .

testing zinc coating thickness|zinc plating thickness chart